BACKGROUND

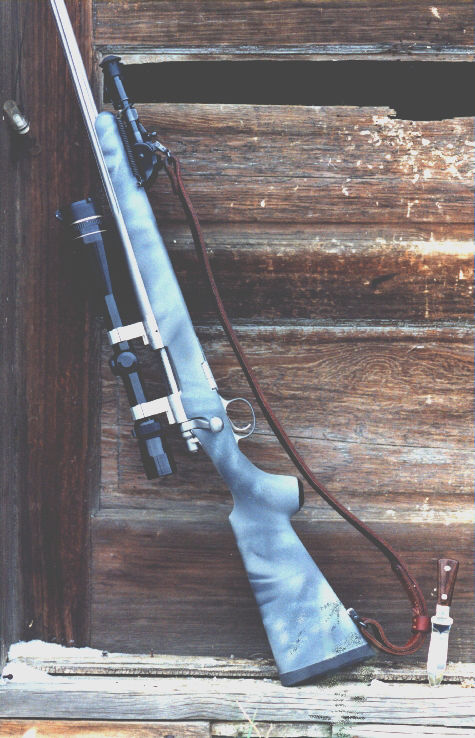

I have been in the Composites business Since 1987. Building racecar parts, contained air system helmet components, Custom core boxes for foundries, etc. Until recently gunstocks were just a hobby to fund my own gun habit. Back around 1993 a bench-rest shooter friend of mine came into the shop to show me his new stock. I shot my mouth off and said I could build a better stock than that. He said prove it. Being the stubborn ass that I am I had to try. I wanted to create a stock that came out of the mould with a better finish was light weigh and very rigid. Well that was easier said than done. 2 years of spare time 3 moulds and about 20 stocks in the garbage I finally had a product that I liked. Then one day at a gun show in Edmonton I was introduced to Rod Schram from Rocky Mountain Rifles in Dawson Creek, British Columbia. He said my stocks were nice but he was building lightweight mountain rifles and I couldn’t possibly build a stock as light as so and so. Well I love a challenge so Rod sent me a model 7 stock and I set out to prove him wrong. Well that was fun, after trying a couple of different moulds and techniques as well as a myriad of different composite materials each delivering different qualities to the finished product. I started to feel like Goldie Locks you know this stocks to brittle, this stocks to heavy, this stocks to hard to finish, this stocks to flexible, finally after trying hand lay-up, vacuum bagging, bladder moulding, resin transfer, I settled on wet on wet compression moulding, which allowed me much more flexibility

In how I could configure each stock.